- BY CATEGORY

- Aluminium sheets

- Aluminium shapes and circles

- Bags, purses, wallets and pencil cases

- Business & promo gifts incl keyrings

- Christmas

- Clothing, headwear, footwear & masks

- Display panels, photoblocks, plaques

- Drinkware

- Fabrics

- SubliFlock, SubliSatin, SubliFabric

- Kid's stuff

- Kitchen & Home

- Pet products

- Photogifts

- Slipmats

- Soft toys

- A-Z ALPHABETICAL LISTING

- A-Z listing of all our sublimation imprintables

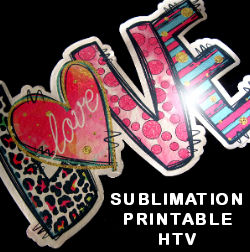

- SUBLIMATION PRINTABLE HTV

- SPECIAL OFFERS

- ESSENTIALS AND PACKAGING

- Essentials

- Mug packaging - cardboard mailers

- Mug packaging - acetate boxes

- HEAT PRESSES

- Flat presses

- Mug presses

- SUBLIMATION OVERVIEW

- Dye Sublimation Overview

- SAWGRASS SUBLIMATION PRINTERS

- Sawgrass Virtuoso SG500 & SG1000 printers

- BYPASS TRAYS

- Virtuoso A3 bypass trays

- Virtuoso A4 bypass tray

- SUBLIMATION INKS

- Virtuoso SubliJet ink cartridges

- Ricoh SubliJet ink cartridges

- SUBLIMATION PAPER

- True Pix dye sublimation paper

- WASTE INK TRAYS

- Virtuoso waste tray

- Ricoh 3110/7100 waste tray

- Ricoh 7000 waste tray

- Ricoh 3300/7700 waste tray

- HEAT PRESSES

- Flat presses

- Mug presses

- HTV BY THE METRE

- Overview page

- Dae Ha One Flex

- Dae Ha Metallic *

- Dae Ha Stretch Metallic

- Dae Ha Holographic *

- Dae Ha Chameleon

- Dae Ha Design Film *

- Dae Ha 3D Puff

- Dae Ha Premium Glitter *

- Dae Ha Flock

- Dae Ha PU printable film & app tape *NEW*

- HTV CAMEO/CRICUT STRIPS

- Overview page

- Dae Ha One Flex

- Dae Ha Metallic *

- Dae Ha Stretch Metallic

- Dae Ha Holographic *

- Dae Ha Chameleon

- Dae Ha 3D Puff

- Dae Ha Premium Glitter *

- Dae Ha Flock

- * Metallic, Holographic, Premium Glitter and Design Film can be sublimation printed

- HTV PORTRAIT STRIPS

- Overview page

- Dae Ha One Flex

- Dae Ha Metallic *

- Dae Ha Stretch Metallic

- Dae Ha Holographic *

- Dae Ha Chameleon

- Dae Ha 3D Puff

- Dae Ha Premium Glitter *

- Dae Ha Flock

- SIGN VINYL

- 5 year sign vinyl *NEW*

- Weeding tools

- APPLICATION TAPE

- Application Tape

- FROG JUICE & 3m SPRAY

- Frog Juice

- 3M SPRAY ADHESIVE

- 3m Repositionable Spray Adhesive

- TRANSFER REMOVAL SPRAY

- Transfer removal spray

- LOOSE RHINESTONES & STUDS

- Loose hotfix rhinestones

- Loose hotfix rhinestuds and shapes

- CUSTOM MADE RHINESTONE DESIGNS

- Custom hotfix rhinestone and rhinestud designs

- RHINESTONE & RHINESTUD ALPHABETS

- Hotfix rhinestone and rhinestud alphabets

- PREMADE RHINESTONE & STUD DESIGNS

- Premade hotfix rhinestone designs

- RHINESTONE AND STUD STARTER PACKS

- Rhinestone and rhinestud packages

- Download our 'How to' PDF guides

- STENCIL TEMPLATE MATERIAL

- Stencil template material

- APPLICATION TAPE

- Application tape

- SAWGRASS CHROMABLAST

- Sawgrass ChromaBlast A3 and A4 systems

- ChromaBlast cartridges & media

- INKJET PAPER DARK FABRICS

- Darkjet inkjet paper for dark cottons

- EMBROIDERED BADGES

- Heat seal embroidered badges

- SILHOUETTE CAMEO CUTTERS

- Silhouette Cameos

- Silhouette Studio upgrades

- COTTON PRINTABLES

- Cotton household textiles & Santa sacks

- Cotton t-shirts

- SUNANGEL LASER CONSUMABLES

- 64CW consumables

- 33TW, 63TW, 83TW cartridges and drum units

- Toner/drums for 8432 & 7411 printers

- Legacy SunAngel 32 consumables

- LASER PAPERS

- One Step print on light laser paper

- SPECIAL OFFERS